Detalle noticia

Finanzauto, Top Employer 2026: un reconocimiento que nace de nuestras personas

22 January 2026

En Finanzauto celebramos un logro que nos impulsa a seguir creciendo: hemos sido certificados como Top Employer 2026, y lo conseguimos por segundo año consecutivo, mejorando incluso la puntuación del año anterior. Este hito confirma algo que forma parte de nuestra identidad: las personas son el centro de todo lo que hacemos.

Un reconocimiento que valida nuestra forma de trabajar

La certificación Top Employer no es un simple sello. Es el resultado de un análisis internacional que evalúa más de 250 prácticas de RRHH y audita cómo se aplican en la realidad. Haber superado este proceso demuestra que nuestra cultura no solo se diseña, sino que se vive cada día.

Bienestar, desarrollo y escucha activa

El avance de Finanzauto en esta edición se debe a un compromiso firme con lo que más importa: el bienestar y el crecimiento de quienes forman parte de nuestra compañía.

Nuestros pilares:

- Desarrollo del potencial humano: espacios y herramientas para crecer profesional y personalmente.

- Equilibrio laboral-personal: iniciativas que facilitan una vida más saludable y sostenible.

- Diversidad e inclusión: un entorno donde cada voz suma y cada perspectiva impulsa la innovación.

- Comunicación transparente: canales abiertos que fortalecen la confianza y la colaboración.

Un futuro que construimos juntos

Ser Top Employer 2026 nos posiciona como un referente en el sector industrial y como un lugar donde las personas pueden desarrollarse, aportar y sentirse parte de un proyecto sólido. Pero, sobre todo, este reconocimiento es un agradecimiento a cada persona de Finanzauto. Su compromiso, talento y energía diaria son la verdadera razón por la que hoy celebramos este logro.

Seguimos avanzando, juntos, hacia una cultura cada vez más humana, más sólida y más inspiradora.

Analizamos los retos de la industria española para 2026 en Radio Intereconomía

05 January 2026

En una reciente intervención en el programa 'Cierre de Mercados' de Radio Intereconomía, conducido por Javier García Viviani, nuestro Director de Marketing, Francisco Martos, desgranó los retos que marcarán la hoja de ruta del sector durante este 2026.

Estas reflexiones nacen de los datos extraídos del Estudio sobre la Industria en España, un exhaustivo análisis desarrollado por Finanzauto en colaboración con la consultora GAD3, que pone de relieve el papel vertebrador de la industria en nuestra economía.

Visualiza la Entrevista en este vídeo:

Radiografía del sector: El motor de la economía y el empleo de calidad

Durante la entrevista, nuestro director de marketing subrayó que el sector industrial no es solo una pieza más del engranaje económico, sino su motor principal: aporta un 16% al PIB nacional, es líder en exportaciones y genera empleo de alta calidad, estable y especializado.

Sin embargo, para seguir impulsando esta posición, el sector debe superar barreras estructurales que podrían condicionar su crecimiento futuro.

Los pilares del cambio: Talento, Inversión, Sostenibilidad y Percepción Pública.

Durante su intervención, Francisco Martos identificó algunos de los ejes fundamentales que la industria debe abordar con urgencia para asegurar su desarrollo.

La falta de profesionales cualificados es seguramente el reto más destacado. En este caso, Francisco Martos señaló la formación como la herramienta esencial para cerrar esta brecha. Destacó la Escuela de Operadores de Finanzauto, una iniciativa pionera con la que formamos operadores de maquinaria a través del uso de simuladores de última generación, fomentando la percepción del sector industrial como un entorno más profesionalizado y, sobre todo, una opción de futuro atractiva para los jóvenes.

Otro elemento clave para impulsar nuestra competitividad es la apuesta por la innovación tecnológica y la eficiencia energética, elementos clave para modernizar y actualizar nuestros procesos y recursos.

También, el sector debe estar comprometido con el medio ambiente y debe llevar a cabo su desarrollo de la mano de la sostenibilidad. Sin embargo, esta transición debe ser alcanzable y real, adaptada a la situación actual de nuestras infraestructuras y recursos.

Por último, durante la entrevista se resaltó la imagen pública de nuestra industria. Y es que nuestro estudio sobre la industria revela una percepción pública asociada a entornos "duros y poco atractivos". El reto reside en comunicar la realidad de una industria moderna, digitalizada y esencial para el bienestar social.

En definitiva, esta intervención refleja nuestro compromiso por aportar claridad a la hoja de ruta del sector. A través de los datos obtenidos, buscamos sumar nuestro esfuerzo al de toda la industria, impulsando desde nuestra posición los recursos necesarios para afrontar juntos estos desafíos.

Finanzauto analiza junto a GAD3 el Sector Industrial en España

18 November 2025

EL MOTOR SILENCIOSO DE NUESTRA ECONOMÍA

En Finanzauto creemos firmemente en el papel estratégico de la industria española como motor de crecimiento, innovación y estabilidad. Con el objetivo de entender mejor su situación actual y su percepción social, hemos impulsado junto a la consultora GAD3 el estudio “El sector industrial en España”.

Este análisis ofrece una visión integral de la relevancia del sector industrial, aportando contexto, evaluando su conocimiento entre la población y valorando su impacto en el desarrollo económico del país.

Conclusiones Relevantes del Estudio:

Descubre aquí el Estudio completo

La industria española: un pilar económico esencial pero poco visible

El estudio revela que la industria española representa el 16% del PIB, concentra el 45% de la inversión privada en I+D y genera casi tres millones de empleos directos, con salarios un 18% superiores a la media nacional.

Además, el 70% de las exportaciones españolas tienen origen industrial, consolidando su papel clave en la balanza comercial y en la competitividad del país. Desde la automoción hasta la química o el sector agroalimentario, la industria impulsa la innovación y la sostenibilidad del tejido productivo.

A pesar de su peso, el sector continúa siendo un “motor silencioso”, con una visibilidad menor que otros sectores como el turismo, pese a su contribución decisiva a la riqueza nacional.

Empleo estable, innovación y transformación tecnológica

El estudio destaca que nueve de cada diez empleos industriales son indefinidos, y que más de la mitad de los trabajadores poseen formación técnica o universitaria. Este nivel de cualificación convierte al sector en un referente en empleo estable, especializado y bien remunerado.

Asimismo, la industria concentra casi la mitad de la inversión privada en innovación, con un tercio dedicada a proyectos de sostenibilidad y transición energética, situándose en el centro de la transformación tecnológica y climática de España.

El desafío del relevo generacional en la industria

Uno de los grandes retos que identifica el informe es el relevo generacional. Actualmente, solo un 12% del alumnado opta por formación profesional industrial, lo que podría dejar más de 100.000 vacantes sin cubrir.

A esta situación se suma la necesidad de romper estereotipos: muchos jóvenes siguen asociando la industria a entornos duros o masculinizados, lejos de la realidad de un sector cada vez más digitalizado, automatizado y sostenible.

La percepción social del sector industrial en España

Aunque la mayoría de los ciudadanos reconocen la importancia de la industria, cuatro de cada diez españoles afirman no estar informados sobre las políticas de apoyo al sector.

Casi la mitad perciben que la industria se ha modernizado en la última década, especialmente entre los jóvenes y las personas con estudios superiores, pero todavía existe un déficit de visibilidad que limita su reconocimiento público.

Brecha con Europa y necesidad de una reindustrialización

El análisis comparativo con Europa muestra que el gasto público en industria en España (0,4% del PIB) es la mitad del que destinan países como Alemania (0,8%). Además, el peso industrial nacional (16%) sigue por debajo de la media europea (20,5%).

Estos datos evidencian un amplio margen de mejora y la necesidad de una política industrial más ambiciosa que fortalezca la autonomía estratégica y la competitividad del país.

No es casual que ocho de cada diez españoles reclamen una reindustrialización: una oportunidad para reforzar la innovación, la sostenibilidad y el empleo de calidad en España.

En Finanzauto, comprometidos con el futuro de la industria española

En Finanzauto llevamos más de 90 años acompañando a la industria española en sus retos, innovaciones y procesos de transformación. Con la elaboración de este estudio junto a GAD3, reafirmamos nuestro compromiso con el sector industrial, que consideramos esencial para el desarrollo económico, tecnológico y social del país.

Seguiremos trabajando para dar visibilidad al papel clave de la industria y para impulsar, junto a empresas, instituciones y profesionales, una España más industrial, más innovadora y más sostenible.

Esta Navidad, brindemos por lo invisible

Descubre el poder de lo invisible en el vídeo de Navidad de Finanzauto de este año.

Lo Invisible envuelve nuestras ilusiones, enciende nuestras alegrías y nos arroja luz cuando más lo necesitamos. Lo invisible hace posible la Navidad.

EL PODER DE LO INVISIBLE, EL PODER DE LA INDUSTRIA

El vídeo de este año es una concsecuencia de las conclusiones que hemos sacado en nuestro estudio sobre la Industria en España, realizado junto a GAD3. El estudio confirma su relevancia como motor económico, generador de empleo y base de las exportaciones, aunque su visibilidad social y mediática no refleja su verdadero peso.

En Finanzauto buscamos poner en valor esta actividad, recordando que detrás de nuestro día a día hay trabajo, conocimiento y una cadena que opera de forma constante, incluso cuando no se ve

Conclusiones Relevantes del Estudio:

Descarga aquí el Estudio completo

Finanzauto y Stadler: 20 años de innovación ferroviaria con Motores Cat®

23 October 2025

Desde hace más de dos décadas, Finanzauto y Stadler colaboran estrechamente en el desarrollo e integración de soluciones de propulsión diésel y bimodales que hoy circulan por las principales redes ferroviarias de Europa y otros países del mundo.

Una alianza tecnológica que ha permitido impulsar la innovación en el sector ferroviario y posicionar a ambas compañías como referentes en eficiencia, fiabilidad y sostenibilidad.

20 años de colaboración e innovación conjunta

La relación entre Finanzauto y Stadler comenzó en 2004, con el suministro de 160 Motores Cat® 3508 para los ferrocarriles estatales franceses (SNCF).

Desde entonces, ambas compañías han trabajado de forma conjunta en múltiples plataformas, evolucionando hacia tecnologías bimodales y motores de última generación que cumplen los estándares medioambientales más exigentes del mercado (Stage V).

Entre los modelos desarrollados en colaboración destacan:

EURO4001 – Locomotora diésel pura, destinada principalmente al tráfico de mercancías.

EURODUAL – Plataforma bimodal con Motor Cat C175, capaz de operar tanto en modo eléctrico como diésel. Presente en países como Alemania, Austria, Turquía, Francia y Escandinavia.

EURO9001 – Último desarrollo de Stadler, con dos Motores Cat C32, que alcanzan hasta 9 MW en modo eléctrico y 2 MW en diésel, ofreciendo una flexibilidad excepcional en los corredores europeos.

EUROLIGHT – Locomotoras para tráfico mixto (mercancías y pasajeros) con versiones diésel y bimodal equipadas con Motores Cat. Finanzauto ha adaptado los motores para cumplir requisitos de emisiones y facilitar el mantenimiento.

Locomotoras en Finlandia – Locomotoras con Motores Cat C32 de 950 kW, diseñadas para operar en condiciones extremas de frío (-40 °C) y vías con gálibos reducidos. Finanzauto desarrolló soluciones de postratamiento compactas y resistentes, adaptadas al entorno nórdico.

KiwiRail (Nueva Zelanda) – Locomotoras de mercancías con Motores Cat C175, adaptadas a túneles de gálibo estrecho y condiciones exigentes de operación. Finanzauto colaboró en el rediseño del postratamiento, instalándolo dentro del compartimento diesel en tiempo récord, optimizando espacio, peso y eficiencia.

Más que un distribuidor: ingeniería, integración y soporte global

El papel de Finanzauto va mucho más allá del suministro de motores.

Como distribuidor oficial de Caterpillar en España, Finanzauto ofrece un servicio completo de ingeniería e integración, participando activamente en el desarrollo, validación y postventa de cada proyecto ferroviario.

Esto incluye desde la adaptación de motores a gálibos reducidos, el diseño de postratamientos específicos, hasta la optimización para climas extremos como los -40 °C de los proyectos nórdicos.

Además, la cobertura global de Caterpillar garantiza a Stadler un servicio postventa internacional, asegurando la disponibilidad de piezas y asistencia técnica en cualquier país donde opere la locomotora.

“La relación entre Stadler y Finanzauto se remonta a hace más de 20 años. Finanzauto no solo distribuye los motores Caterpillar, sino que participa en todo el proceso de desarrollo, integración y validación. Su capacidad de respuesta, soporte técnico y colaboración continua son clave para el éxito de nuestras locomotoras.”

— David Blanco Rodríguez, Head of Mechanical Systems en Stadler Valencia

Mirando hacia el futuro

Finanzauto continúa acompañando a Stadler en el desarrollo de nuevas plataformas ferroviarias sostenibles y eficientes, integrando los motores para que cumplan con los requerimientos más exigentes.

Una colaboración que demuestra cómo la ingeniería, la innovación y la confianza mutua pueden hacer realidad los proyectos de motorización más complejos.

No te pierdas el reportaje completo sobre la relación de Finanzauto y Stadler y descubre todos los detalles de estas dos décadas de excelencia y mejora continua:

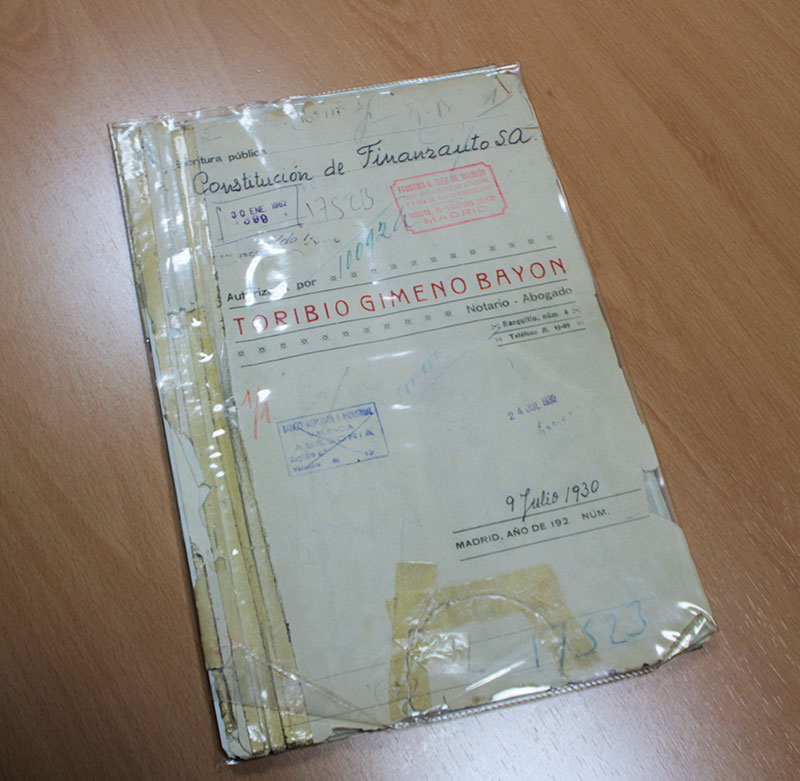

90th Anniversary of the Founding of Finanzauto

09 July 2020

It was July 9, 1930, when, with a share capital of 500,000 pesetas (€3,000), Finanzauto Sociedad Anónima was established with the initial purpose of granting loans for the acquisition and sale of automobiles.

Over the years, the company evolved, expanding into the sale of agricultural tractors, trucks, and public works machinery from prominent national and international brands: Delaport, Penta, Continental, DKW… consolidating in 1949 when it was appointed distributor of Pegaso trucks.

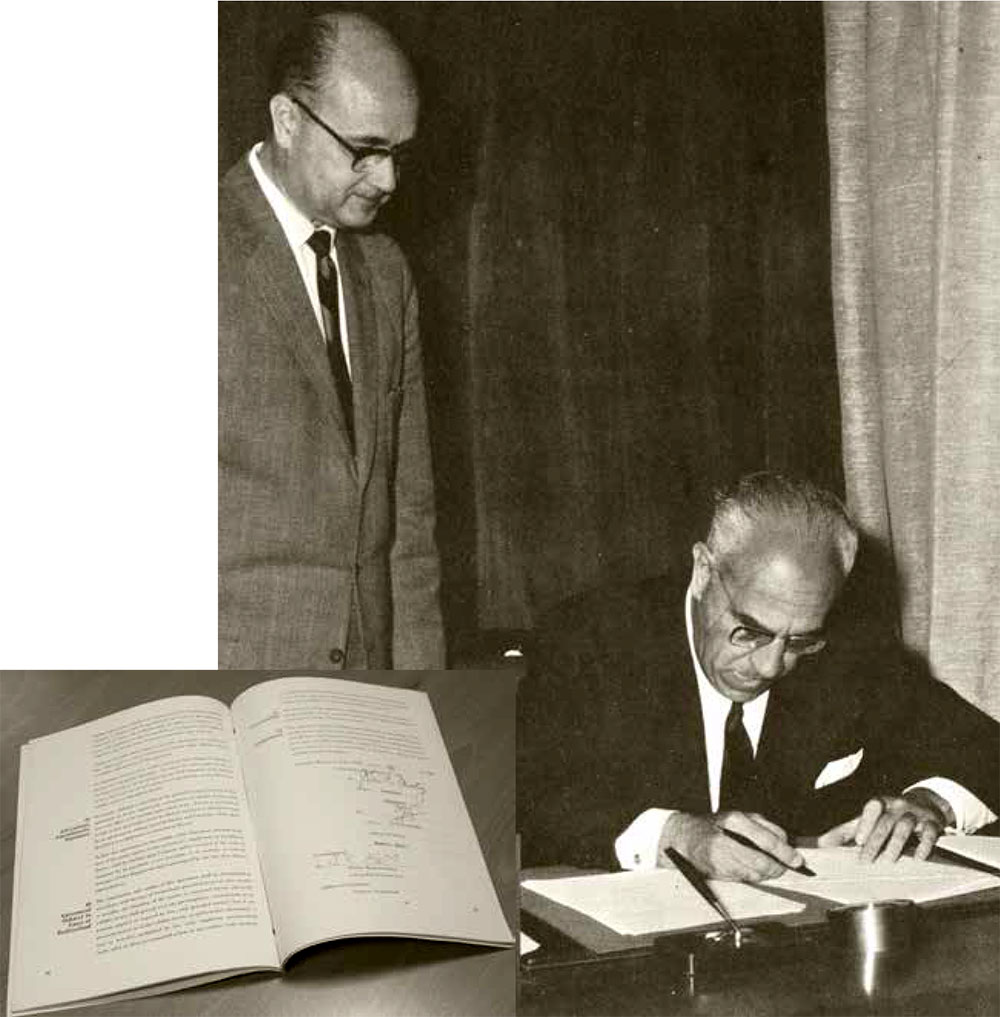

In the following years, we continued expanding, securing the distribution of leading brands of that era. This situation, along with the solidity, organization, and structure that Finanzauto demonstrated, was the reason Caterpillar appointed the company as exclusive distributor in Spain for its manufactured products. The agreement was signed in Geneva on May 31, 1963.

More than 55 years have passed since this signing, and Finanzauto has continued evolving to remain a modern and advanced company, adapting to and overcoming many challenging situations that have arisen.

During this period, we have established ourselves as the reference company in all markets where we operate, thanks to our continuous commitment to providing the best service to our clients, always at their disposal to find the best solution for them and their businesses.

The result of this is the prestige we enjoy and, what fills us with the most pride, the loyalty of our clients.

Today, and after 90 years since the company’s founding, we can boast unmatched strength and solidity. This dynamic of evolution, adaptation, and modernization is more present than ever following our integration into TESYA Group almost 2 years ago.

Over the past 2 years, Finanzauto has been in continuous transformation. We are building a much more modern, digital, and technologically advanced company, adapted to the current times we live in.

We have expanded our product portfolio, securing distribution of prestigious brands: Sandvik, Konrad, Noe, Prinoth, Rotor…

But this does not stop here, and we continue working to explore new lines of action to provide a more comprehensive solution to our clients, improving our market presence, and consolidating ourselves as a stronger and more resilient company.

And, to conclude, we cannot fail to mention the most representative achievement we have accomplished as a company, the construction and consolidation of OUR VALUES.

This proposal, linked to the group’s name change, allows us not only to identify with the group but also helps us consolidate and enhance our brand image.

The values presented by the group, thanks to the work of everyone, will allow us to recognize ourselves and will represent our DNA as members of TESYA Group.

We cannot think of a better way to celebrate these 90 years of existence and continuous evolution of Finanzauto than the moments we are experiencing now, thanks to this group identity and value proposition.

We are convinced that, with the strength of the people who make up Finanzauto, we will celebrate 90 years living up to our motto: “You and I, empowering the growth of people, companies, and communities.”

90th Anniversary Logo

Incorporation of Finanzauto S.A.

Caterpillar Agreement

Sales Convention

90th Anniversary Image

Certified Used Cat® Machines

22 May 2019

Eliminate any doubts: With a Cat Certified Used machine, you can be confident it’s truly in optimal condition to work.

Before you put a Cat Certified Used machine to work, we put it to the test.

Each Certified Used machine is selected, inspected, and serviced following our most recent maintenance standards and adjusted to meet our high-quality requirements:

-

Minimum 6-month warranty on powertrain and hydraulic system, according to manufacturer conditions

-

Maintenance history available for units coming from our rental fleet

-

Rigorous inspections covering more than 140 check points

-

Option to add a customized maintenance contract

Every low-hour, well-maintained machine must undergo a strict quality inspection that includes up to 140 check points to qualify as “certified.” Once the machine passes all tests, we perform the required preventive maintenance using genuine Cat parts, backed by Caterpillar warranty, and connect it to Product Link® technology (when applicable) to monitor your machine’s performance at all times and help you optimize its productivity.

Finanzauto Best Marine Dealer Worldwide

17 December 2015

On April 15, Finanzauto was awarded the “Global Dealer Excellence Award” for its Marine Division. The award was received by Clive Thomson from Doug Oberhelman (Chairman and CEO of Caterpillar®) in Dubai, during the ceremony in which Finanzauto was the only dealer worldwide to receive an award in the marine business.

This achievement has been made possible thanks to the steps taken by FINANZAUTO, which are fully aligned with Caterpillar’s marine business strategy, based on:

-

Development of the complete propulsion business

-

Continuous proactivity and willingness to develop new products (with Finanzauto being the only pilot dealer in EAME for the propeller business)

-

Commitment to other products such as EMD

-

Development of the aftersales business (especially in the MaK® engine area)

-

Achievement of certifications such as MSA Platinum

This award, which recognizes the excellence of our marine business above other traditionally leading dealers, would not have been possible without our fantastic team of professionals, who day by day have elevated this business to a higher level and form the great Finanzauto family. Our sincere thanks to all of them.

This award, which recognizes the excellence of our marine business above other traditionally leading dealers, would not have been possible without the fantastic team of professionals who, day by day, have elevated this business to a higher level and make up the great Finanzauto family. Our sincere thanks to all of them.

With the award (from left to right): Rob Charter (Chairman of the Caterpillar Group), Clive Thomson, and Doug Oberhelman (Chairman of the Board and CEO of Caterpillar).

Finanzauto Inaugurates Its New Hydraulic Center

27 September 2013

On September 27, the new Finanzauto Hydraulic Center was inaugurated, located within the Base Arganda facilities. This exclusively designed building features a fully equipped workshop prepared for the rebuilding of hydraulic cylinders, as well as a new and innovative center for the identification and fabrication of hydraulic hoses.

The inauguration ceremony began at 11:30 AM with the reception of attendees, including:

-

Local authorities, such as the Mayor of Arganda del Rey, Mr. Pablo Rodríguez Salinero; the First Deputy Mayor and Finance Councilor, Ms. Amalia Guillén; and the Councilor for Promotion and Economic Development, Mr. Alejandro Daganzo

-

Caterpillar leadership, represented by Mr. John F. Calder, EAME District Manager

-

Technical press, with around ten editors from the sector’s most prestigious media outlets

-

Finanzauto management, who not only hosted the event but also engaged closely with authorities, clients, and friends, sharing impressions and concerns, as well as enjoying an excellent barbecue that extended into the afternoon

The event was opened by Ms. Isabel Vicente, Finanzauto Post-Sales Director, who thanked everyone for attending and highlighted the importance of the new Hydraulic Center for the company and its clients.

Javier León, Marketing Manager, acted as the master of ceremonies and reminded attendees that 2013 marks the 50th anniversary of Finanzauto’s distribution agreement for all Caterpillar products.

John F. Calder, EAME District Manager of Caterpillar, emphasized that Finanzauto has been the only Caterpillar distributor in the world to receive the highest service excellence award three consecutive times. Referring to the current economic situation affecting several European countries, including Spain, he drew an analogy with a Caterpillar hydraulic hose, highlighting its ability to withstand pressure, flexibility, and adaptability, ensuring optimal performance throughout its life.

The Mayor, Mr. Pablo Rodríguez Salinero, congratulated Finanzauto on the new center and highlighted the company’s importance to the industrial and business development of Arganda del Rey for nearly five decades.

Mr. Oscar Vicente, Head of Hydraulics at Finanzauto, provided a detailed explanation of the operations and functions of the new Hydraulic Center.

Finally, Mr. Justo Galán, Post-Sales Manager of Base Arganda, emphasized the service improvements that Finanzauto can now offer its clients and invited them to start using the new center immediately.

A step forward in After-Sales Service

This new Hydraulic Center complements the extensive range of services that Finanzauto offers its customers for the hydraulic systems of their machines. The Center will carry out two clearly defined activities:

-

Rebuilding of hydraulic cylinders

-

Identification and manufacturing of hydraulic hoses

Both the Cylinder Workshop and the Hose Manufacturing Center are equipped with the most advanced technology, including the following highlights:

Cylinder Workshop

-

Caterpillar Hydraulic Bench for cylinder disassembly/assembly, capable of generating forces and tightening torques of over 7 tons—essential for opening the largest cylinders without damaging their main components.

-

Automated Cylinder Liner Honing Machine. A fully automated machine used for the internal reconditioning of cylinder liners. Capable of handling loads over 3.5 tons, this equipment restores the internal surface finish of the liners, ensuring the repaired cylinder operates smoothly and extending its service life.

-

CNC Machining Center, where the dimensional data for thousands of references—directly obtained from Caterpillar’s manufacturing database—can be pre-programmed. This allows minimal production times when a piston rod requires rebuilding, thereby reducing the return time of the repaired cylinder.

Hose Manufacturing Center

This center is located at the rear of the reception area. Through its large glass windows, clients can observe firsthand the entire process carried out by our specialists when manufacturing a hose.

The center is equipped with the latest hose assembly technology, including the state-of-the-art Caterpillar Radial Press, computer-controlled and capable of assembling high-pressure hoses up to 2½” in diameter, using both permanent fittings and Caterpillar’s exclusive reusable fittings.

It is important to highlight that this specialized center can manufacture hoses and rebuild cylinders for all machine brands, whether Caterpillar or not, allowing complete coverage for any customer’s machinery fleet.

Once again, Finanzauto takes a step forward to offer differentiated solutions and services, focusing on fast, high-quality processes and investing in the latest technologies available on the market.

Finanzauto Inaugurates Its New Hydraulic Center

Finanzauto Opens New Facilities in Barcelona

26 March 2014

After nearly 50 years of presence in Santa Perpètua de Mogoda since 1967, Finanzauto has relocated its Barcelona base to a new, much more modern facility in Barberà del Vallès, equipped with the latest technological advancements, from which it will serve all of Catalonia.

Throughout this time, Finanzauto has aimed to provide high-quality service, always tailored to the specific needs of each client and aligned with the standards of Caterpillar, the globally leading brand it represents, ensuring that service and customer care remain a competitive advantage. However, time inevitably takes its toll, and those facilities—once cutting-edge and advanced for their era—had become somewhat outdated. Finanzauto therefore decided to seek a change in line with the new market demands, convinced that the financial investment, even in these challenging times, was absolutely necessary to continue delivering the best customer service.

To celebrate this milestone, on March 21, 2014, the official inauguration of the new facilities took place, with events beginning at 13:30 and clients invited from 12:00. The ceremony was attended by a large group of clients from across Catalonia, as well as prominent figures such as the Mayor of Barberà del Vallès, Ms. Ana del Frago, the Director General of Industry, Mr. Antoni Mª Grau, Caterpillar leadership represented by Vice President Mr. Cristian Dillier, and the national management of Finanzauto led by CEO Mr. Viktor Salzmann.

Facilities

Located in the Santiga-Provasa Industrial Estate of Barberà del Vallès, the new site offers an excellent location, with easy access and high visibility from the AP-7.

Built on a 20,000 m² plot, the facilities include:

-

1,717 m² of workshops, with 7 lanes, overhead cranes of 5, 6.3, 10, and 12.5 tons, and all necessary tools for any repair

-

838 m² of annex workshop, including a clean waste area, paint, welding, and chain shops, and washing areas

-

1,433 m² of modern offices across 2 floors

-

550 m² spare parts warehouse

From these new facilities, the Company will continue to actively contribute to the development of Catalonia in particular and Spain in general, just as it has done over the past 47 years. Of course, the doors of Finanzauto will remain open to all clients and friends, welcoming them to visit what, from this date forward, will also be their home.

Finanzauto Opens New Southern Base Facilities in Seville

26 October 2015

Located very close to its previous site, in the Ibárburu Industrial Estate of Dos Hermanas and on a 30,000 m² plot, this is the Company’s new headquarters, following 45 years of operations at its former location.

This move was driven by two main reasons: on one hand, to continue offering all customers in the provinces served by this Base the best service and attention, which required updating the facilities and equipping them with state-of-the-art systems, tools, and technologies to ensure the continuity of the leadership the Company has maintained for over 50 years. The second reason was to continue the Company’s investment and facility renewal plan, which has been underway in recent years despite Spain’s challenging economic situation, with new centers launched in Gran Canaria, Tenerife, Valladolid, Arganda (Hydraulic Center), and Barcelona.

The new Base Sur serves 12 provinces: the eight Andalusian provinces, two in Extremadura, and the autonomous cities of Ceuta and Melilla. In addition to this facility, the Company operates centers in Macael (Almería), Granada, Algeciras (Cádiz), Málaga, Córdoba, and Mérida (Badajoz). The site employs 117 professionals with proven experience. Key figures include:

-

Total area: 30,000 m²

-

Built area: 5,000 m²

-

Offices: 1,590 m²

-

Main workshop: 1,750 m²

-

Annex workshop: 888 m²

-

Spare parts warehouse + storeroom: 812 m²

Main Workshop Facilities:

-

7 double lanes

-

4 overhead cranes (5 tons) + 3 overhead cranes (6.3 tons)

Annex Workshop Facilities:

-

Wash bay

-

Paint shop

-

3 welding lanes

-

Recycling/clean point

The inauguration ceremony welcomed nearly 400 clients, along with prominent local and regional authorities, including His Excellency, the Mayor of Dos Hermanas, Mr. Francisco Toscano, and the Regional Delegate for Economy, Innovation, Science, and Employment of the Andalusian Government, Ms. Susana López Pérez. Also in attendance were Mr. Richard Bliss, General Manager of Caterpillar® Paris Office, Mr. José Coronel de Palma, President of Caterpillar Financial, and, of course, the Finanzauto Management team, led by its President and CEO, Mr. Viktor Salzmann.

The event began at 12:00 noon with the reception of guests, who were able to view an extensive exhibition of Cat® products and six dedicated information points covering Finanzauto’s commercial offering across its different business areas.

At around 12:30, guided tours of the new facilities began, allowing attendees to see the various departments, warehouses, workshops, and other areas of the Company firsthand. A highlight of the tour in the main workshop was the demonstration of the rebuilding processes for large production equipment, showing real-life examples of the “before and after” of an interior mining Cat® R2900 loader.

At 13:30, the official inauguration took place, featuring speeches by Finanzauto and Caterpillar® authorities, followed by the traditional ribbon-cutting and unveiling of the commemorative plaque.

Finally, after a group photo beside the machinery exhibition, all attendees shared a cocktail reception, celebrating a future full of success for everyone.

50 Years of History Between Finanzauto and Caterpillar

04 February 2015

As many know, during 2014 we celebrated the 50th anniversary of the distribution agreement between Finanzauto and Caterpillar.

To conclude the celebrations, we created a commemorative book and video summarizing these five decades.

In both, we aimed to highlight the most significant milestones in Finanzauto’s history, shaped by the hard work of all our employees and the trust our customers have placed in us year after year.

The book is available on our website via the following link, and the video can be viewed on our YouTube channel.

We hope you enjoy the book and video and can see reflected the impact that you or your companies have had on these 50 years of Finanzauto’s journey.

50 Years of History Between Finanzauto and Caterpillar

The TESYA Group Launches CYCLICA

The TESYA Group, parent company of Finanzauto, has launched CYCLICA, an international and connected platform that aims to become a global benchmark for sustainable development in the industry.

The new platform offers a stock of thousands of machines, engines, spare parts, and other industrial equipment available to clients, supported by specialists capable of providing the best personalized advice. The team behind CYCLICA works daily to provide accurate information on the condition of listed equipment. This industry expertise and knowledge make the platform a reliable reference for acquiring machinery, industrial equipment, and reconditioned spare parts.

Felipe Fernández-Urrutia, TESYA Group’s Director of Used Equipment, stated:

"Initiatives like CYCLICA represent a step forward in the sector leadership of Finanzauto and its parent company, the TESYA Group. With CYCLICA, we offer our clients the opportunity to give equipment a second useful life, acquiring machinery and spare parts that maintain optimal quality and performance, establishing a new way of approaching used equipment sales based on sustainability and user trust."

CYCLICA also represents a strong commitment to the circular economy, extending the lifespan of equipment and significantly reducing the use of raw materials and energy required to manufacture new components. With this approach, CYCLICA aims to become the leading global platform for reconditioned equipment, prioritizing transparency and quality in the information provided about the equipment. In this way, Finanzauto strengthens its role as an innovative leader, driving positive transformation in the industry and developing solutions that enhance efficiency and cutting-edge performance in the sector.

50th Anniversary of the Finanzauto and Caterpillar Agreement

29 May 2013

On May 31, 1963, the agreement between the two companies was signed.

We want to share with everyone that on May 31, we celebrated 50 years of collaboration between Finanzauto and Caterpillar. On this occasion, we also wish to highlight other important milestones in our company’s history, in which we have had the great satisfaction of being not only spectators but also participants—and in many cases, key players—through our customers.

In Madrid, on July 9, 1930, Finanzauto, S.A. was founded. From that moment until 1962, the company’s business focused on the financing and sale of automobiles, agricultural tractors, trucks, and public works machinery from various prominent brands. Those over 30 years of expansion provided the company with the stability necessary for Caterpillar, the global leader in earthmoving equipment, to offer exclusive distribution of its products in Spain to Finanzauto, S.A.

The agreement was signed in Geneva, Switzerland, on May 31, 1963. Since then, 50 years of significant milestones have passed, crucial both for the company’s expansion and for the economic growth of our country.

In the same year, 1963, Caterpillar launched its new Industrial Division, dedicated exclusively to the development and manufacture of engines, located in Mosville, north of Peoria, Illinois. One of the initial challenges was to adapt the facilities to business demand.

In 1967, the first three Bases were inaugurated: Arganda, Barcelona, and Valencia, followed by Tenerife in 1968, the same year the company received its first Model Company award in Social Security.

Between 1969 and 1974, seven new Bases were opened in Oviedo, Zaragoza, Bilbao, Sevilla, Las Palmas, Málaga, and Coruña, along with delegations in Lérida and Palma de Mallorca.

In 1973, coinciding with the 10th anniversary of the distribution agreement with the American brand, a major meeting was held in Madrid, during which Caterpillar congratulated all Finanzauto employees for achieving the #1 sales volume among distributors worldwide.

In February 1976, the Advisory and Training Center was launched in Arganda del Rey, inaugurated by the then Minister of Education and Science, Mr. Robles Piquer.

In 1990, Finanzauto, S.A. acquired a majority stake in the Portuguese company STET, the Caterpillar products distributor in Portugal.

Today, the company boasts a consolidated, young, dynamic, and expert team, fully prepared to face the future with enthusiasm and a clear goal: to continue working hand in hand with our clients, helping them achieve maximum profitability from their Caterpillar equipment and, consequently, their businesses. The pursuit of excellence and continuous improvement makes our daily work a stimulating and motivating challenge, allowing us to continue growing and to keep Progressing Together for at least another 50 years.

Finanzauto Participates in Repsol Casablanca Offshore Platform Project (Tarragona)

23 February 2015

Facilities

The Casablanca platform, located 52 km from Tarragona, extracts a portion of the crude oil processed at the Complex. The platform rises 75 m above sea level and produces around 8,000 barrels of crude oil per day from the reservoir and six wells: Rodaballo, Boquerón, Barracuda, Chipirón, Lubina, and Montanazo.

The Casablanca facilities are divided into three main sections:

-

The fixed platform, built in an area with a depth of 161 meters.

-

The subsea wells, connected to the platform and controlled remotely.

-

The pipeline, which transports crude oil from the sea to the coastal terminal for subsequent distribution within the Complex.

The Pantalán, Repsol’s maritime terminal, covers nearly 9,000 m² and provides five docking fronts for unloading vessels of up to 100,000 tons. In addition, the terminal includes a single-point mooring (SPM) buoy located 3 km offshore, where supertankers can discharge their cargo.

The project

The project originated approximately one year ago, in collaboration with Repsol’s Engineering Department, with the aim of improving the current power generation and distribution system of the producing platform, which is composed of the following generator sets:

The client identified the need to replace the 3512 diesel generator due to age and power limitations. This unit has been in service since 1997 and has accumulated over 26,000 operating hours.

After analyzing the initial situation and planning the platform’s future power requirements, various feasibility studies and proposals were presented to the client.

Among the potential alternatives in this first phase were the 3516 DGB (Dynamic Gas Blending) and the 3516B HD models.

Subsequently, during the project development, Repsol’s Engineering Department assessed that while these units would be suitable for current operating conditions, they might face limitations considering the estimated power increases for new platform projects.

Given this new situation, the initial proposals were revised to consider 1,500 rpm generator sets with higher power density, specifically the Caterpillar C175-16 and the new C175-20 models.

Once the feasibility of installing any of these units at the current 3512 location was verified by Finanzauto’s Power Systems Engineering Department in collaboration with Repsol, the client issued a tender for the equipment purchase.

Finally, following the tender process, in December 2014, Finanzauto was awarded the contract for the supply and commissioning of a Caterpillar C175-20 diesel generator with 2,880 ekW of main power, including engine cooling skid, control panel, auxiliary services, and FAT testing.

Generator Set Specifications

PRIME power 2880 ekW 3600 kVA 50 Hz 1500 rpm 600 Volts

We Move Our Bilbao Facilities

16 February 2018

It’s been almost 50 years since we began our operations at the Amorebieta facilities in Bilbao, back in 1970. Throughout this time, we have strived to offer our customers high-quality service, always tailored to their specific needs and in line with the standards of Caterpillar®, the world-leading brand we proudly represent.

But time moves on, and those facilities—cutting-edge and advanced for their time—eventually became outdated. It was time for a change to meet new demands, and we got to work.

After the necessary stages of searching, selecting, and building, we are pleased to announce the opening of our new facilities, equipped with everything needed to provide impeccable service and customer care, along with convenient access for goods, machinery, employees, and visitors alike.

Since February 19, 2018, all our operations have been carried out at Finanzauto’s new facilities in Ortuella, located at:

Polígono Industrial El Abra Industrial - Plot 1.5.1

48530 ORTUELLA (Vizcaya)

GPS: Long: W 3º 3' 59.277" | Lat: N 43º 18' 57.197"

Please note that our opening hours, telephone, and fax numbers remain unchanged:

Tel.: 946 730 500

Fax: 946 730 554

From these new facilities, we will continue to actively contribute to the development of our region in particular and Spain as a whole—just as we have done over the past 48 years. And, of course, we warmly invite you to visit us at what, from now on, will also be your home.

Statement March 29: Finanzauto and Essential Activities

30 March 2020

Dear Customer,

Finanzauto, as it could not be otherwise, will remain close both to the companies that continue working to guarantee the services considered essential, and to those that have had to stop their operations, making sacrifices, to contribute to the fight against contagion.

We have a firm commitment to society and to our country, so at this moment of great uncertainty, we continue working with all necessary resources. We want to contribute so that no sector or essential service in the fight against the coronavirus stops, such as hospitals, supermarkets, law enforcement, freight movement, logistics centers, landfills, agriculture, fishing, forestry, and passenger transport, among others.

In this regard, we inform you that we are at your disposal following the measures adopted by the Extraordinary Council of Ministers on Sunday, March 29, regarding the Restriction of Movement for all persons who are not part of essential activities in the fight against COVID-19 that we are currently facing.

If you consider that your activity or service is of an essential nature and need to request our assistance, please complete the following form and send it to your contact person or to the following customer service address: consultas@finanzauto.es. This document explicitly states that your company is part of one of the categories providing essential services and activities exempt from the restrictions established by the Government, and that it requires our services under the terms you deem necessary.

We will continue contributing our bit to overcome this crisis as soon as possible and in the best way. Together we will overcome it, and together we will celebrate it in the company of our loved ones and friends.

Pierre-Nicola Fovini

CEO Finanzauto, S.A.U.

New Agreement Between Finanzauto, STET, and Sandvik

07 July 2020

From Finanzauto and STET, we will distribute the Sandvik mobile crushing and screening line in Spain, Portugal, and Cape Verde.

Thanks to this new agreement with Sandvik, Finanzauto and STET expand our portfolio of products and after-sales services with industry-leading products in quarrying, mining, recycling, and public works machinery.

From Finanzauto and STET, we will distribute a wide range of Sandvik mobile crushers and screeners, in addition to offering rental solutions and a complete after-sales service. Customers will benefit from this new agreement for Spain, Portugal, and Cape Verde due to the extensive network that Finanzauto and STET provide, supported by a team of nearly 1,300 professionals across more than 30 bases and branches.

Sandvik is a global, high-tech engineering group with approximately 42,000 employees and sales in over 160 countries. Its main focus is on improving customer productivity, profitability, and business sustainability, perfectly aligning with the mission and vision of Finanzauto and STET.

Since 1930, Finanzauto, and since 1956, STET, have been providing services and solutions to our clients, and we have been official Caterpillar distributors for over 50 years. In 2018, we became part of TESYA, a group established in Southern Europe that offers integrated solutions and rental services across a wide range of industries, including quarries, mines, public works and infrastructure, road construction, demolition, terrestrial and marine power systems, and forestry operations.

This agreement, signed in June 2020, strengthens and expands the solid collaboration that Sandvik and the TESYA group have maintained in Italy since 2016. The Finanzauto and STET family welcomes the Sandvik mobile crushing and screening line.

“We work together”

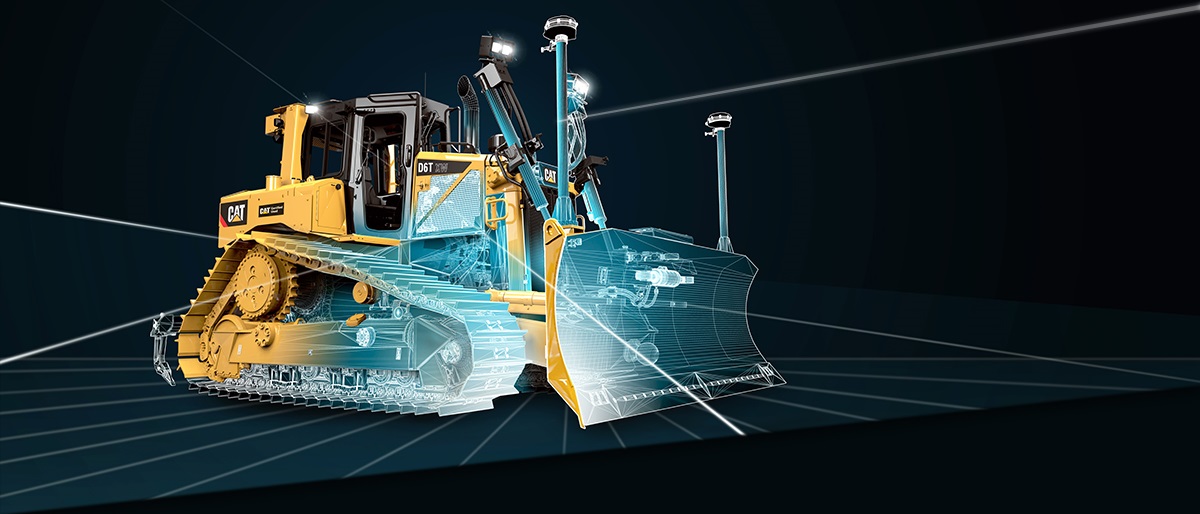

Cat® 330 and 336 Excavator Demonstrations + Cat Grade 3D System

18 January 2021

Do you want to learn about our Cat® 330 or 336 Excavator with Cat Grade 3D System?

Starting January 27, we will hold demonstrations in various areas of the peninsula, and you can ask for more information.

Demonstration Schedule |

|---|

Cat 330 Excavator + 3D Cat Grade System Demonstrations (January 27 to February 15) |

Cat 336 Excavator + 3D Cat Grade System Demonstrations (February 22 to March 15) |

Of course, we will comply with all COVID-19 regulations and safety protocols and ensure that all necessary measures are in place so that the demonstrations are safe environments.

Vídeo demostración

Finanzauto | Cat® 330 Excavator + Cat Grade 3D System

Comunidad de Madrid Awards

25 February 2021

Despite the challenges posed by the COVID-19 pandemic, the third edition of the Comunidad de Madrid Awards, organized by LA RAZÓN, took place on February 24. Sixteen companies were recognized in the presence of Ignacio Aguado, Vice President of the Community of Madrid; Andrés Navarro, CEO of LA RAZÓN; and Francisco Marhuenda, Director of LA RAZÓN.

Finanzauto was honored with the “Leadership in Heavy Machinery Distribution” award for its longstanding track record in the sector and for the work and effort the company has devoted to advancing society’s development and well-being.

We would like to thank LA RAZÓN, as the organizer of the awards, and the Community of Madrid for granting this prestigious recognition. We also extend our congratulations to the other awardees, including Universidad Pontificia Comillas, Mascarillas Béjar, Oximesa, Pladur®, Athlon Car Lease Spain, Construcciones Ruesma, Carrier España, among others, all of whom exemplify leadership in their respective industries.

Our CEO, Pierre-Nicola Fovini, accepted the award on behalf of the company. In his speech, he highlighted Finanzauto’s contribution over more than 90 years to the development and progress of Spain’s infrastructure and society, collaborating with key industries that have driven the nation’s growth.

María José Sáez, journalist and presenter from Antena 3, hosted the event and introduced Finanzauto as:

“The official distributor and after-sales service provider in Spain for the world’s largest heavy machinery and engine manufacturer. Thanks to this partnership, Finanzauto has grown since its founding in 1930 to establish an extensive network of offices and branches across Spain.”

She also emphasized that:

“Finanzauto is a multi-specialist company with a prominent role as a systems integrator across multiple industrial sectors, providing service throughout Spain.”

Receiving such an award in these challenging times is a testament to the company’s resilience and commitment.

Adicionalmente resaltó que “Finanzauto es una empresa multi-especialista con un destacado rol como integradores de sistemas en múltiples sectores de la industria con servicio en toda España.”

En un momento tan complicado como el que vivimos, tiene mucho mérito poder recibir un premio de esta categoría.

Message from our CEO, Pierre-Nicola Fovini

In his closing remarks, our CEO stated:

“I would like to highlight that this award is the result of the dedication and tenacity of nearly 1,000 people who work at Finanzauto every day with a clear goal and motivation: to continue contributing to the progress of Spanish society, and particularly that of the Madrid region.”

We would like to once again thank LA RAZÓN and the Community of Madrid for this recognition, and we look forward to participating in the 2022 edition of the awards.

For further information, the article in LA RAZÓN can be found here:

https://www.larazon.es/economia/20210225/u6wbdy6ipvbubdslg47ujijtb4.html

Mensaje de nuestro CEO, Pierre-Nicola Fovini

Pierre-Nicola Fovini (CEO of Finanzauto)

Ignacio Aguado (Vice President of the Community of Madrid), Pierre-Nicola Fovini (CEO of Finanzauto), and Francisco Marhuenda (Director of La Razón)

Javier León (Head of Marketing), Pierre-Nicola Fovini (CEO of Finanzauto), and Fco. José Martos (Marketing Director)