Detalle Productos Cat

14568023

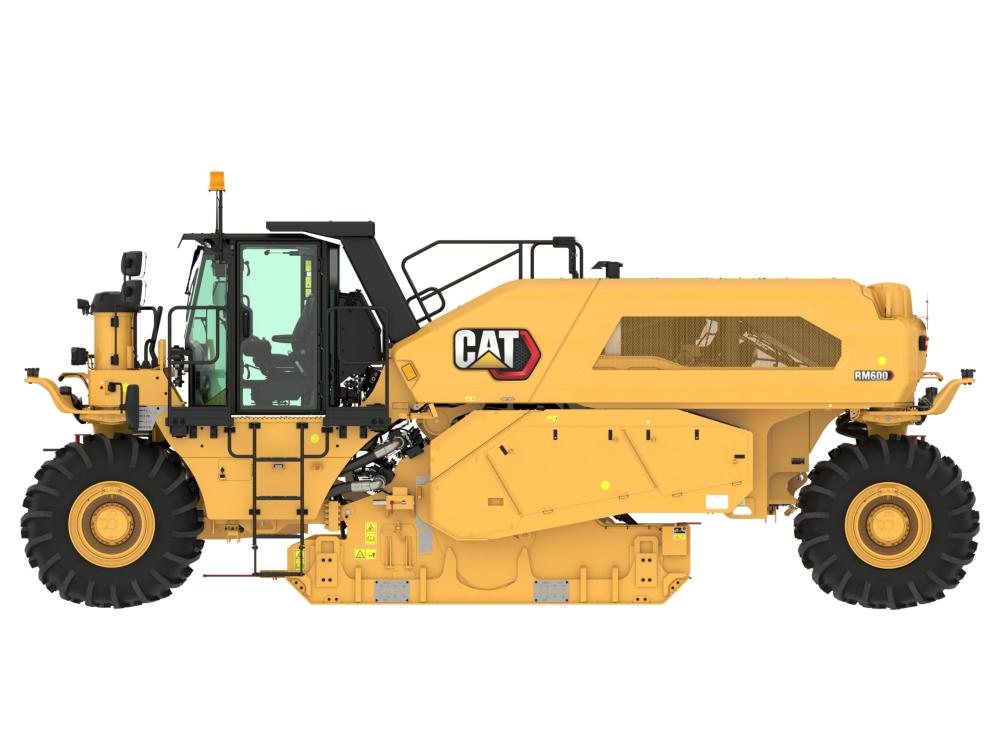

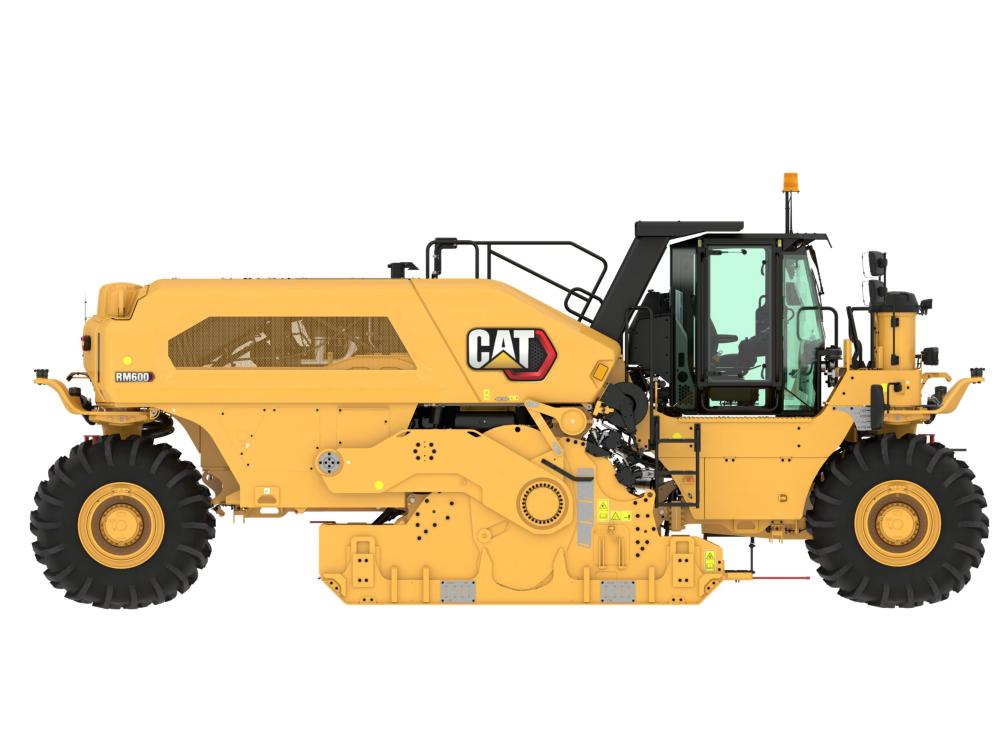

Road Reclaimers

- Machines

- Pavement recyclers and soil stabilisers

- RM600 Road Reclaimer

15704101

RM600 Road Reclaimer

Cat

https://www.finanzauto.es/productos/recicladoras-de-pavimentos-caterpillar-recuperador-de-caminos-rm600

Metric

Imperial

Maximum Operating Weight

35600 kg

78484 lb

Cutting/Mixing Width

2.44 m

8 ft

Gross Power

475 kW

637 hp

Availability

Power, Performance and Productivity

Optimum weight distribution with features like All-Wheel Drive and a powerful Cat® engine aim to maximize cutting and mixing performance.Feature-filled Operator Environment

The ergonomic operator station is designed to provide maximum visibility and is equipped with features to help simplify operation.Highly Versatile

Engineered to be highly maneuverable and ideally suited to work in a variety of applications and terrain with a Cat System K rotor designed to deliver quality material.Efficient Power and Performance

Maximize Productivity and Mix Quality from the Cab

Operator Visibility and Comfort

Simple to Operate, Easy to Learn

Optional Spray Systems Perform with Precision

Durable and Dependable Cutting System

Cat System K Rotor for Reclamation and Stabilization

Easy Service, More Uptime

Sustainability

- Powerful Cat® C18 engine meets regional emission standards.

- A 4-pump, electronically-controlled, all-time All-wheel drive system in combination with well balanced machine weight helps maximize traction and mobility.

- Front-to-rear weight distribution provides stability in tough cuts.

- Wheels positioned on the corners of the machine provide the smallest inside and outside turning radii to help you maneuver in tight spaces, enhanced by four steering modes: front wheels only, rear wheels only, crab steering, and coordinated steering

- 8.72 m (28.61 ft) overall machine length helps enhance maneuverability in compact spaces.

- Four height adjustable legs provide up to 14% (8 degrees) of positive or negative slope on either side when working on uneven terrain or to maintain traction in challenging soil stabilization applications.

- The belt-driven rotor provides flush cut capability on the right-hand side.

- Advanced electronic features with Automatic Load Control help deliver ideal mix quality and maintain production efficiency by adjusting the machine speed to match material conditions.

- Utilize the full range of rotor speeds without leaving your seat.

- Easily modify material gradation by adjusting the front and rear mixing chamber doors and an easy-to-read indicator on the touch screen display informs the operator of door positions.

- To help operators simplify operation, the hydraulic down pressure that is applied to the rear door can be adjusted when using the float feature to automatically maintain the desired door position.

- Exit and Return-to-cut features help operators save time and maintain consistency with the simple tap of a button.

- Standard FOPS cab comes with heating and air conditioning for a comfortable work environment and is audio-ready with speakers.

- Control your preferred sight lines from the driver's seat with the full-machine width sliding cab and 180º rotating operator station.

- Touch screen displays can be positioned to preferred viewing angle.

- Operator visibility to the cutting path is enhanced with floor to ceiling glass and an angled pane on the right-hand side provides a clear view to the leading edge of the cutting chamber.

- A heated, air-ride suspension seat with high visibility seat belt is equipped with fore and aft adjustment to help increase operator comfort and visibility.

- Performance and safety can be augmented with standard and optional cameras that are viewed on large, in-cab displays:

- Fore and aft visibility is enhanced with front and rear mounted cameras with on-screen configurable guidance lines

- Obstacle avoidance and gradation results can be viewed with cameras mounted above the front and rear mixing chamber doors

- Visibility to each side of the machine can be supplemented with an upgrade to side mounted cameras

- Convenience features include USB ports for charging, 12V DC outlets, multiple storage compartments, phone and cup holders.

- Easily match machine functions with gradation specifications through the 25 cm (10 in) color touch screen displays and push button controls.

- Controls are ergonomically located and grouped by function for quick and easy access.

- A multi-function joystick puts speed, rear steering and primary rotor controls at your fingertips.

- Precise machine control is delivered through hand-wheel steering.

- Start the engine with a push button; use a Bluetooth key fob or the Operator ID passcode for added security and to recall saved operator preferences and profiles upon login.

- Water and emulsion additive systems are available for a variety of applications.

- Additive application rate is monitored with a computerized metering system for accuracy.

- Customize spraying width by turning spray nozzles on or off through the touchscreen display in the cab.

- Spray bars conveniently slide out on either side for inspection, cleaning and service.

- Push bar is stored within the hitch at ground level for easy access.

- A wide range of variable flow rates help meet specifications:

- Water flow rates from 30-1900 liters per minute (8-500 gallons per minute)

- Emulsion flow rates from 30-850 liters per minute (8-225 gallons per minute)

- The Emulsion Spray System is capable of delivering bitumen emulsion or water with self-cleaning nozzles designed to reduce maintenance and provide a consistent spray pattern.

- Easily set up the spray system to deliver liquid additives according to specifications:

- Manual or automatic

- Volume per minute

- Volume per m2 (yd2)

- Percent of material density

- The rotor drive system features a hydraulically-actuated, heavy-duty dry clutch that does not require adjustment.

- Electronically-controlled drive line protection.

- Two high tensile, six-rib belts with automatic belt-tensioning to prevent slippage.

- Bi-directional cutting capability.

- Durable, high-strength, variable volume cutting chamber.

- Visual indicators inform ground personnel of cutting depth and rotor position when working around obstacles.

- The System K rotor is designed to deliver high quality results on a variety of projects utilizing proven toolholder and base block components from our cold planer System K rotor.

- Components are manufactured with abrasion-resistant, high-strength alloys to help withstand tough, high-power applications.

- Tools are precisely placed on the rotor to aid in delivering ideal material sizing and homogeneous mixing results.

- Triple-tree cutting bit placement on rotor ends cleans up loose material and helps reduce wear on the rotor caused by maneuvering in the cut.

- The Cat System K rotor is configured with bolt-on wedge-shaped toolholder protection that can be rotated 180° for extra life.

- A fastener-free design secures toolholders in place without a retaining pin, bolt or setscrew, speeding up replacement and eliminating the need for torqueing.

- Replaceable toolholders can be selected for use with 20 or 22 mm shank bits and offer multiple methods for bit removal.

- Toolholder protection, endring segments and endring wear protection plates bolt-on for simplified reconditioning.

- Routine checkpoints are centrally located and safely accessed on a secure platform.

- Monitor fluid conditions with regular sampling to help extend change intervals up to 500 hours engine oil, 6000 hours hydraulic oil and 12000 hours coolant.

- The auto-reversing cooling fans help prevent debris build-up, extending maintenance intervals for cleaning the cooling package.

- A standard compressed air system with two access points powers pneumatic tools to speed up rotor bit changes and can be used for general machine cleaning and maintenance.

- Ground-level controls and optional hydraulically-powered rotor turning with pendant simplify bit replacement and rotor cleaning.

- Easily inspect or change triple-tree components using the access door on the either side of the rotor chamber.

- Optional high-pressure wash system for convenient clean-up.

- Built-in diagnostics monitor machine systems, alert the operator of performance issues and provide troubleshooting information.

- The accessory drive system allows use of select machine functions when the engine is off.

- Electrical system wiring is color-coded and numbered for easy identification and wrapped in a protective, abrasion-resistant nylon braid for longer life and reliability.

- VisionLink® provides actionable data insights for all assets – regardless of fleet size or equipment manufacturer.* Review equipment data from your desktop or mobile device to maximize uptime and optimize assets. Dashboards provide information such as machine hours, location, idle time, fuel utilization and diagnostic codes. Make informed decisions that lower costs, simplify maintenance, and improve safety and security on your jobsite.

- Remote Flash allows you to update onboard software without a technician being present, allowing you to initiate software updates when convenient to help increase your overall operating efficiency.**

- Remote Troubleshoot allows your Cat dealer to perform diagnostic testing on your connected machine remotely.**

* Data field availability can vary by equipment manufacturer and is provided through an application programming interface (API). VisionLink subscription required. Availability may vary by region, consult your Cat Dealer for more details.

** Must be within cell range coverage.

- The Cat C18 engine meets U.S. EPA Tier 4 Final, EU Stage V and Korea Tier 5 emission standards

- Cat U.S. EPA Tier 4 Final, EU Stage V, and Korea Tier 5 diesel engines are required to use ULSD (ultra-low sulfur diesel fuel with 15 ppm of sulfur or less) or ULSD blended with the following lower-carbon intensity fuels up to: 20% biodiesel FAME (fatty acid methyl ester) or 100% renewable diesel, HVO (hydrogenated vegetable oil) and GTL (gas-to-liquid) fuels. Refer to guidelines for successful application. Please consult your Cat dealer or “Caterpillar Machine Fluids Recommendations” (SEBU6250) for details.

- Engine Idle Speed Management helps maximize fuel efficiency and reduce greenhouse gas emissions by elevating engine speed to an intermediate idle to complete specific tasks and returning to low idle when finished.

- Automatic Load Control helps you save fuel and reduces greenhouse gas emissions by automatically matching propel speed to engine load for maximum production at peak efficiency

- Electronically controlled All-Wheel Drive with Traction Control maintains consistent traction to increase machine efficiency, helps reduce fuel burn and greenhouse gas emissions

- Performance and safety can be augmented with standard and optional cameras that are viewed on large, in-cab displays

- Extended maintenance intervals not only reduce downtime but decrease the amount of fluid and filters that are replaced over the life of the machine

- Cat Scheduled Oil Sampling (S•O•S℠) Services helps reveal excessive wear, contaminated fluids or other “unseen” issues that can shorten component life. In many cases, you can extend oil and coolant change intervals by using fluid monitoring. Consult your Cat dealer or the machine's operation and maintenance manual for more information.

- The engine, hydraulic system and Diesel Exhaust Fluid (DEF) tank (if required) are equipped with ecology drains for easy servicing and to help prevent spillage

- Don't waste fuel idling. Cat VisionLink® online fleet monitoring helps you manage idle time and reduce fuel burn and greenhouse gas emissions

- VisionLink displays the CO2 emissions for monitored assets, calculated by fuel type for the Runtime Fuel Burned each day in a selected date range

- Remote Troubleshoot decreases maintenance time and keeps your machine running with maximum efficiency by allowing your Cat dealer to virtually test the machine while working. Once a problem is identified, a technician can fix it the first time, saving time and money.

- Remote Flash minimizes downtime and maintenance time while keeping your asset running with maximum efficiency. Alerts for machine updates are sent virtually from your Cat dealer and updates can be deployed without a dealer technician needing to be onsite.

Weights

| Maximum Operating Weight | 35600 kg | 78484 lb |

| Note (1) | Maximum weight is approximate and includes base machine, all options, coolant, lubricants, rotor, full fuel tank, full water tank, full DEF tank and 75 kg (165 lb) operator. |

Operating Specifications

| Cutting/Mixing Width | 2.44 m | 8 ft |

| Maximum Cutting/Mixing Depth | 508 mm | 20 in |

| Rotor Options | System K | |

| Rotor Drive | Belt | |

| Operating Speed | 65 m/min | 213 ft/min |

| Maximum Travel Speed | 12.1 km/h | 7.5 mile/h |

Engine

| Gross Power | 475 kW | 637 hp |

| Engine Power | 469 kW | 629 hp |

| Engine Model | Cat C18 | |

| Emissions | U.S. EPA Tier 4 Final, EU Stage V, Korea Stage V | |

| Build Number | 01A |

Dimensions

| Length | 8.72 m | 28.61 ft |

| Width | 3 m | 9.8 ft |

| Maximum Height | 3.5 mm | 11.5 ft |

| Wheel Base | 7.05 m | 23.13 ft |

| Ground Clearance | 506 mm | 19.9 in |

Service Refill Capacities

| Fuel Tank Capacity | 1230 l | 325 gal (US) |

| DEF Tank | 47 l | 12.4 gal (US) |

| Cooling Systems | 99 l | 26.1 gal (US) |

| Engine Oil | 68 l | 18 gal (US) |

| Hydraulic Tank | 120 l | 31.7 gal (US) |

| Washdown Water Tank | 454 l | 120 gal (US) |

Sustainability

| Recyclability | 98% |

You might also be interested in:

Other categories of Equipos:

-

Mini Excavators

-

Small Excavators

-

Magni fixed telehandlers

-

Compact Wheel Loaders

-

Medium Excavators

-

Magni rotating telehandlers

-

Small Wheel Loaders

-

Large Excavators

-

Magni heavy duty telehandlers

-

Medium Wheel Loaders

-

Demolition Excavators

-

Manipuladoras telescópicas agrícolas

-

Large Wheel Loaders

-

Wheel Excavators

-

.jpg)

Chippers

-

Forestry forwarders

-

Underground Mining Equipment

-

Mobile stockpillers

-

Compactors

-

Landfill Compactors

-

Vibratory Soil Compactors

-

Soil Compactors

-

Screens

-

Scalper screens

-

Mobile Trommel screens

-

Underground Mining Trucks

-

Articulated Trucks

-

Mining Trucks

-

Off-Highway Trucks

-

Underground mining equipment

-

Long Reach Excavation

-

Excavators

-

Minig excavators

-

Asphalt Pavers

-

Track Asphalt Pavers

-

Wheel Asphalt Pavers

-

Cold Planers

-

Impact

-

Attachments

-

Mobile crushers and screeners

-

Jaws

-

Material Handlers

-

Track Material Handlers

-

Magni Telehandlers

-

Recycling Machines

-

Forestry machinery

-

Skid Steer Loaders

-

Tracked skid steer loaders

-

Wheeled skid steer loaders

-

Cone crusher

-

Motor Graders

-

Wheel Tractor-Scrapers

-

Elevating Scrapers

-

Track Loaders

-

Wheel Loaders

-

Forestry processors

-

Backhoe Loaders

-

Tandem Vibratory Rollers

-

Crawler tractors

-

Wheel Dozers

-

Mobile Shredders

-

High-Spedd Mobile Shredders

-

Low-Speed Mobile Shredders

-

Shredder vehicles

-

Windrow Turners

360º Interior

360º Exterior

Virtual Tour

RM600 Road Reclaimer

Call us

I am interested

I am interested

Thank you for contacting us.

We have received your request and will contact you as soon as possible.

Please check your email to ensure that the form has been sent correctly.