Detalle Productos Cat

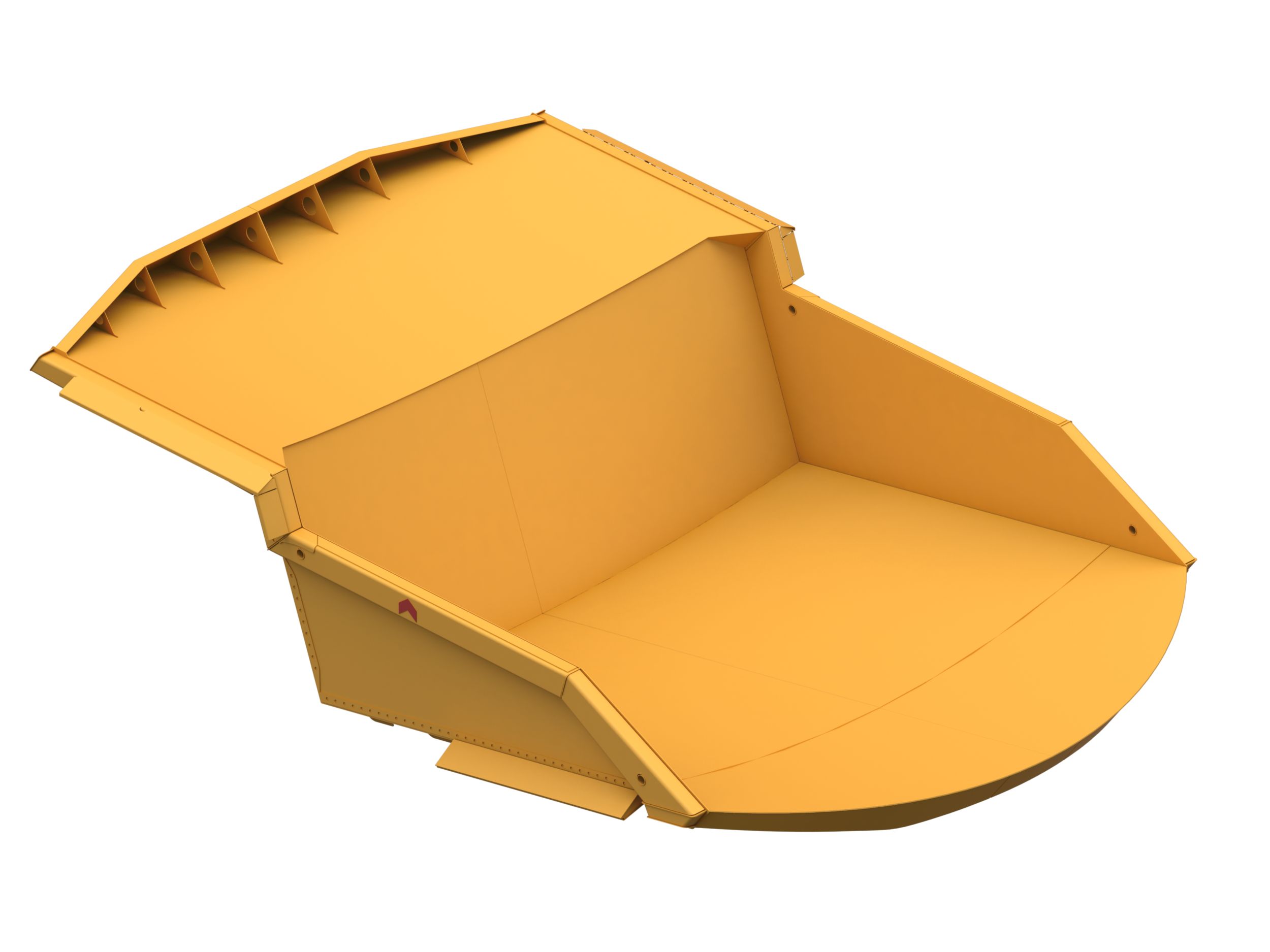

P224 Secondary Pulverizer

Metric

Imperial

Cycle Time - Open

1.9 s

Cycle Time - Close

1.3 s

Crushing Force - Primary Cutter

3640 kN

Availability

Cat® Pulverizers are perfectly matched to Cat excavators so you can deliver productive concrete demolition without compromising performance or machine health. Cat P200 Series Secondary Pulverizers are designed to reduce the size of debris, clear up a job site, and separate concrete from rebar at ground level after demolition.

HIGH PERFORMANCE

EASY TO MAINTAIN

RELIABILITY AND DURABILITY

BOOST EFFICIENCY AND PRODUCTIVITY WITH INTEGRATED TECHNOLOGIES

VERSATILITY AND CONVENIENCE WITH COUPLERS

- Cat pulverizer jaws are designed to cut through material quickly to enhance your machine’s overall operating efficiency and help reduce fuel consumption.

- The oversized cylinder on the non-rotating secondary pulverizer delivers a strong crushing force to reduce concrete and separate rebar.

- The Speed Booster valve actively balances speed and power, delivering fast cycle times and strong closing force to help increase productivity.

You might also be interested in:

-

>

-

P214 Secondary Pulverizer

Cycle Time - Open

1.6 s

Cycle Time - Close

1 s

Crushing Force - Primary Cutter

2345 kN

>

-

P218 Secondary Pulverizer

Cycle Time - Open

1.8 s

Cycle Time - Close

1.2 s

Crushing Force - Primary Cutter

3125 kN

>

-

P232 Secondary Pulverizer

Cycle Time - Open

1.9 s

Cycle Time - Close

1.4 s

Crushing Force - Primary Cutter

4265 kN

Compatible machines:

-

323

Net Power - ISO 9249

128.5 kW

Operating Weight

25000 kg

Maximum Digging Depth

6730 mm

-

326

Net Power - ISO 9249

149.8 kW

Operating Weight

25600 kg

Maximum Digging Depth

6820 mm

-

326

Net Power - ISO 9249

149.8 kW

Operating Weight

25600 kg

Maximum Digging Depth

6820 mm

-

326

Net Power - ISO 9249

149.8 kW

Operating Weight

25600 kg

Maximum Digging Depth

6820 mm

Other categories of Implementos:

P224 Secondary Pulverizer